Product Advantages:

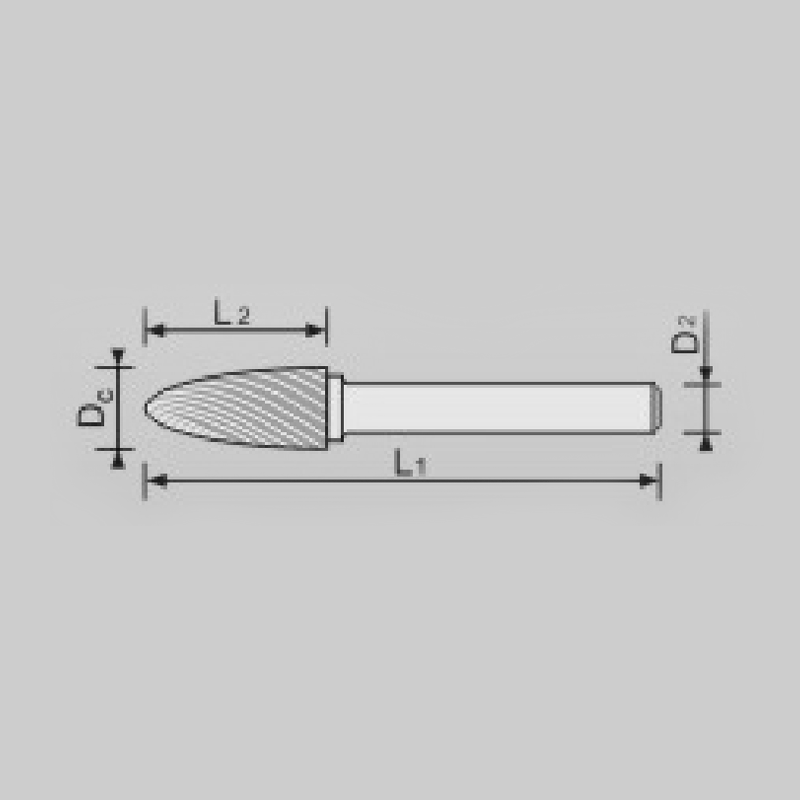

1. Tree-Shape Radius Design:

- The distinctive tree-shape radius end of the RBF-Cylindrical bur enables precise shaping and smoothing of intricate contours, including inner corners and tight curves.

- This unique design facilitates access to hard-to-reach areas, enhancing efficiency and minimizing the need for additional tools or manual finishing.

2. Efficient Material Removal:

- With tightly arranged cutting flutes, the RBF-Cylindrical bur ensures swift and efficient material removal, optimizing productivity during grinding and shaping tasks.

- The strategic distribution of cutting edges enhances chip evacuation, preventing clogging and maintaining consistent performance even in demanding applications.

3. High-Quality Surface Finish:

- The RBF-Cylindrical bur is engineered to deliver surface finishes, characterized by smoothness and precision.

- Each pass of the bur results in a refined surface texture, reducing the need for secondary finishing processes and enhancing overall workpiece quality.

Product Features:

1. Durable Construction:

- Crafted from premium-grade materials, the RBF-Cylindrical bur exhibits exceptional durability and longevity, ensuring prolonged service life even in rigorous industrial environments.

- The robust construction of the bur withstands high-speed operations and heavy-duty applications, maintaining performance consistency over extended periods.

2. Precision Cutting Performance:

- The precise alignment and geometry of cutting flutes on the RBF-Cylindrical bur ensure consistent and accurate material removal, facilitating intricate shaping tasks with minimal deviation.

- This precision cutting performance minimizes the risk of errors or imperfections, allowing for the creation of highly detailed workpieces with tight tolerances.

3. Versatile Compatibility:

- The RBF-Cylindrical bur is compatible with a wide range of rotary tools and grinding machines, offering versatility across various industrial and artisanal applications.

- Whether used in aerospace manufacturing, mold making, or electronic device maintenance, this bur adapts seamlessly to diverse machining requirements.

Product Applications:

1. Aerospace Manufacturing:

- The RBF-Cylindrical bur finds extensive use in aerospace manufacturing facilities for shaping and finishing critical components, such as turbine blades, engine casings, and structural elements.

- Its ability to access tight spaces and achieve precise material removal makes it indispensable for achieving the stringent quality standards demanded by the aerospace industry.

2. Mold Making:

- In the field of mold making, the RBF-Cylindrical bur excels in contouring mold cavities, cores, and intricate details with exceptional accuracy.

- Mold makers rely on its versatility and precision to create molds for plastic injection molding, die casting, and other manufacturing processes, ensuring the production of flawless components.

3. Electronic Device Maintenance:

- Within the realm of electronic device maintenance and repair, the RBF-Cylindrical bur is utilized for precision shaping and modification of electronic housings, circuit boards, and small mechanical components.

- Its ability to navigate complex geometries and delicate components makes it an invaluable tool for technicians and engineers tasked with intricate repairs and modifications.

In summary, the RBF-Cylindrical with radius end stands as a testament to our commitment to delivering cutting-edge solutions for precision grinding and shaping applications. With its unique design, durable construction, and versatile performance, this bur empowers craftsmen, engineers, and manufacturers to achieve results with unparalleled efficiency and accuracy. Elevate your machining capabilities with the RBF-Cylindrical bur and experience the difference in precision and performance.